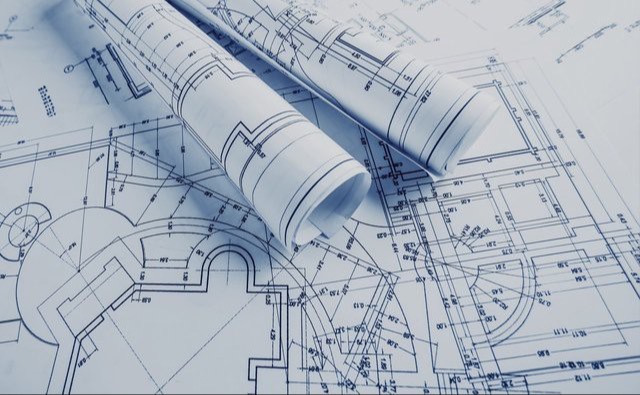

1. Receive drawings and create production plan

- ・Receive design drawings from engineering department or clients.

- ・Develop shop drawings and detailed fabrication drawings.

- ・Create production plan and assign tasks to teams and machines.

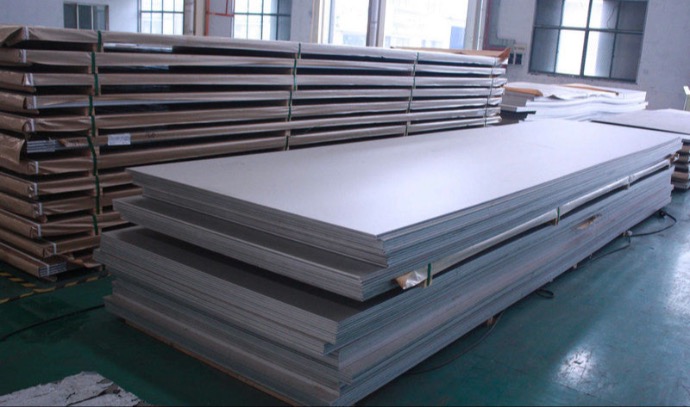

2. Prepare materials and inspect incoming items

- ・Select correct materials: steel plates, profiles (H, I, U, V, pipes, boxes), bolts, base plates, etc.

- ・Check material certificates (CO, CQ).

- ・Measure dimensions, warpage, rust, etc.

- ・Preliminary cleaning: remove rust, oil, and impurities if any.

3. Steel cutting

- ・Cut steel according to drawings using oxy-gas, CNC plasma, or laser machines.

- ・Ensure dimensions are within allowable tolerances (usually ±1 mm).

- ・Mark and classify parts after cutting.

4. Mechanical machining of parts

- ・Drill or punch holes for bolts and base plates using CNC drilling or punching machines.

- ・Bevel and clean edges to prepare for welding.

- ・Bend parts if special shapes are required (hydraulic press).

5. Assembly and welding

- ・Pre-assemble parts according to drawings: beams, columns, purlins, base plates, etc.

- ・Tack weld to fix parts temporarily.

- ・Complete welding by manual arc or CO2 (MAG/MIG) according to approved WPS.

- ・Inspect welds (VT, MT, UT if required).

6. Surface cleaning

- ・Clean surface by sandblasting or rust-removing gun to SA 2.0 – SA 2.5 standard.

- ・Ensure proper surface roughness before painting.

7. Protective painting

- ・Apply anti-rust primer, usually epoxy or alkyd.

- ・Apply topcoat as per design color.

- ・Check paint thickness with specialized device.

- ・Ensure adhesion, thickness, and aesthetics meet standards.

8. Inspection and acceptance

- ・Check dimensions, tolerances, squareness, and warpage.

- ・Inspect weld quality and paint thickness.

- ・Attach label or part number if applicable.

- ・Internal inspection and acceptance with investor/supervisor.

9. Packaging and delivery

- ・Package steel parts using wire, pallets, or containers.

- ・Attach quality documents, drawings, CO/CQ if applicable.

- ・Arrange and transport to site according to plan.